Fire Hydrant System...

Fire Hydrant System

A Fire Hydrant System is emergency equipment or active firefighting equipment that provides a water source to the firefighter to extinguish the fire if a fire disaster occurs. Fire Hydrant System is a source of water supply that delivers water with adequate pressure and flow rate through a network of pipes, nozzles, and hydrants throughout the whole building for firefighting purposes. A hydrant system consists of a network of pipes connected directly to the main water supply source to provide water to every hydrant outlet during an emergency. Every Hydrant has one or more outlets to which a fire hose may be connected. The hydrant system helps out the firefighters in the process of fire suppression. Fire Hydrant System improves or enhances the capacity of firefighters to suppress the fire in the building where it is installed. The fire hydrant system is not only for firefighting purposes but also has other applications such as water transfer.

A fire hydrant system is used in different kinds of buildings to prevent fire to break out.

1. Commercial Buildings.

2. Large Warehouses.

3. Chemicals Industry.

4. Textile & Garment Industry.

5. Petrochemicals & Refineries.

6. Ceramics & Stone Processing.

7. Metal Processing.

8. Manufacturing Units.

Fire Fighter connects a fire hose to the hydrant and opens a valve. When the valve is opened the water comes out from the main water source. Water is discharged into the fire engine and then it is thrown over the fire. The minimum flow rate of the fire hydrant system is 950 liters from the hydrant per minute. In some cases, firefighters connect the hydrant system with other fire safety equipment such as a fire sprinkler system.

Design of Fire Hydrant System

Fire Hydrant System is designed to suppress the fire that has spread over a large area. It is used to suppress the fire of all classes. The design of the hydrant system is based on several operational elements. Pressure and flow rate may vary depending on size, Floor areas, and other specifications of the building. on the Design of the fire hydrant system may vary across different countries.

Some of the points that determine the design of the fire hydrant system are:

- A flow rate of water (liter per minute) is needed for fire suppression.

- Size of the hose connection is required.

- Operating characteristics of the hydrants.

- Static pressure present in the system.

- Climatic conditions of the area.

- Clearance and visibility.

Components of Fire Hydrant System

A Fire Hydrant System consists of a series of components that when assembled provide sufficient water flow and help fire suppressors to extinguish the fire.

The components of the hydrant system are as following:

Water Supply & Water Storage:

Fire Hydrant system’s water supply is obtained from a different source of water such as tank, dams, etc. water storage should include a space for automatic recapturing of the water because there are chances of water loss due to evaporation, leakage, etc. the volume of the water storage facility should be considering as part of the hydraulic analysis (water pressure, water quantity).

Pipework & Valves:

The successful discharge of water from the water source to the destination point (over the fire) requires a network of pipes of different sizes. The sizes of the pipes depend on the hydraulic analysis. The fire hydrant system also includes control valves. The control valves control the flow of water. We use Control valves in combination with pipes.

Fire Brigade Booster:

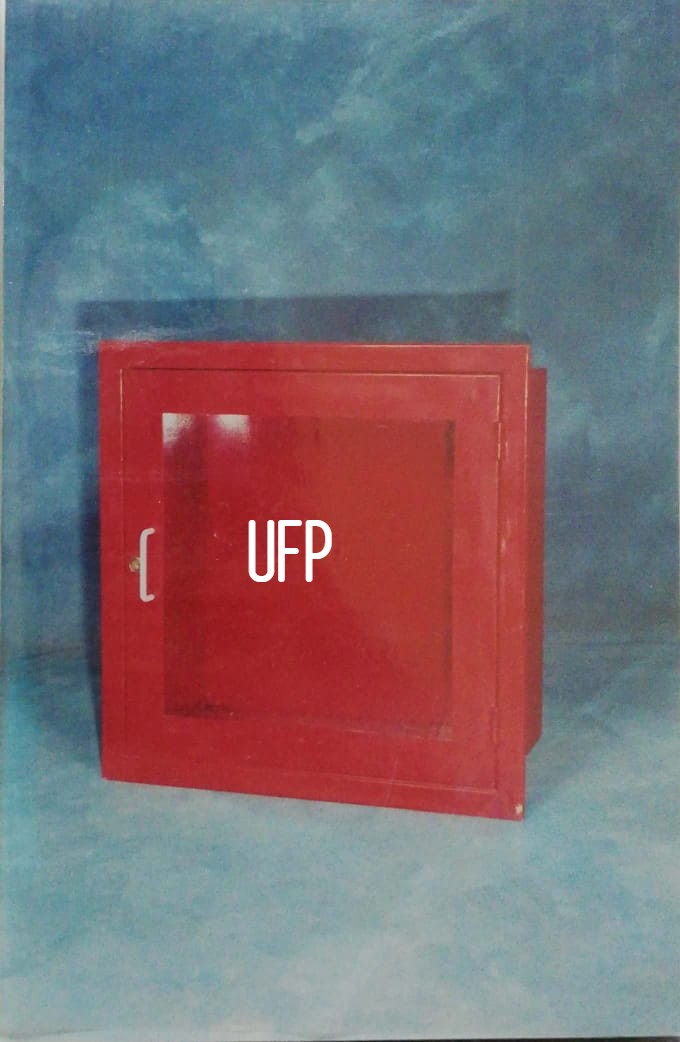

In case of any emergency, the boosters provide a point of attachment to the fire brigade to provide extra water flow to the hydrant system. The booster is basically for the fire brigade. The location of the boosters is chosen to choose the best place from where it is readily accessible and provide protection to fire suppressors. We fit a booster in any cabinet that contains the pressure range and specific requirements of the Fire Hydrant System.

Booster Pump Set:

After the hydraulic analysis, it is determined that the building requires more water supply then booster pumps are connected with a fire hydrant system. A booster pump set includes electric and ignition motors (motors that require diesel as fuel).

Hydrant (also known as the Attack Hydrant):

The hydrant is the main component of the fire hydrant system. The hydrant is also known as the hydrant valve. The hydrant is located throughout the building. The diameter of the hydrant valve connection is 65mm. the connection for the fire hose system varies according to the requirement of the local fire authority. Hydrants should be connected in such a way that they are readily accessible and has adequate clearance (nothing creates a hurdle in viewing the hydrant).

Lay Flat Fire Hose:

Some buildings also require the installation of some additional equipment such as a lay-flat fire hose. The hose is the carrier that carries water with high pressure to extinguish the fire. Lay flat fire hose is made from PVC. Its function is to lay the hose in a flat position. They are used in the delivery of water when water discharge is not easy.

Block Plan:

A fire hydrant system block plan is a memorable diagram in the booster cabinet or fire control room that illustrate the specific features of the system such as the location of the water supply, dimensions, location and capacity of the water tank, location of valves, location of the pumps, pressure and flow rating of pumps, the height of the highest fire hydrant, lower booster connection and so on.

How does the Fire Hydrant System work?

During normal circumstances a fire hydrant system pressurized with water. The water is ready to use in an emergency. When fire suppressors open the firewall the pressure of the waterfalls.

When pressure drops it is detected by a pressure switch gives a call to the booster pumps to start. the booster pump then gives a boosting kick to the water supply to increase the pressure of water in the system. Water is then forwarded by the lay flat fire hose to a nozzle which is then thrown on the fire. During fire suppression, the fire brigade may supply extra water and boost the water pressure to fulfill the demand of the hydrant system. This is carried out by connecting a fire appliance (truck) between an alternate water supply and the booster connection.

Types of Fire Hydrant system

Fire Hydrant System is divided into two types

Dry Barrel Fire Hydrant:

A dry Fire Hydrant is an unpressurized pipe and is permanently installed in the building. This pipe has one end below the level of water of the storage site such as lake and pond. This end has a strainer that blocks any waste material from entering the pipe. The other end of the pipe is above the ground level and has a hard sleeve connector. When the water supply is needed then a pumper fire engine will pump from the water source such as lake and pond by drawing water from it. This is done by vacuuming the air out of the dry hydrant, hard sleeve, and the fire engine pump with a primer. When the air comes out it lowers the pressure at the pump intake, this forces the water forces water into the part of the dry hydrant above water, into the hard sleeve, and finally into the pump. This water can then be passed out by the engine’s pump. It is used in areas where the water supply is not sufficient. It is used in rural areas.

WET FIRE HYDRANT:

All the mechanical parts of the wet fire hydrant are above the ground. The main valve prevents any waste material from entering the hydrant. The outlet valve and nozzles indecently perform their function so that fire suppressors can supply additional discharge lines without shutting down the hydrant. Its operational lifespan is more than 100 years. Wet fire hydrants are easy to maintain. Wet fire hydrants are used in areas where the temperature is high or warm areas. All the mechanical parts of the wet fire hydrants are easy to access above ground and can be adjusted to the proper height without expensive changes. In a wet fire hydrant, the water supply will be made of two interconnected tanks that will feed both duty and standby pumps.

Advantages of Fire Hydrant System

The fire hydrant system is an efficient device and has several advantages. These advantages are as follows.

- The main advantage of a hydrant system is that it can supply a large quantity of water which is pumped through hoses to the fire truck.

- The trucks increase the pressure of water and then divided into several fire hoses as multiple water supplies.

- It is one of the effective systems to extinguish the fire in the building to save the building and people from heavy devastation.

- The system has can suppress the fire from a long distance because of its network of pipes.

- It is highly accessible.

- It is user friendly.

- The valves of the hydrant system are located at different locations and protect the premises from every corner.

Installation of Fire Hydrant system

The fire hydrant system is an efficient device and has several advantages. These advantages are as follows.

- The hydrant system installation requires an above-ground connection. Above ground, connections provide access to the water source for fighting the fire.

- All the parts of the hydrant (water storage reservoir, pump set, piping ring around the building and terminals inside the building, hydrant valves, hose pipes, branch pipes with nozzles hose reel drums) must be installed with proper care. Proper installation is the key point that affects the working of the hydrant system.

- Valves must be located in such a place where they are easily accessible.

- The pump house becomes the heart of the hydrant system especially when it is designed after the complete hydraulic calculations taking into account the flow, velocity, Head, and pumping capacity with the corresponding reservoir to extinguish the hazard and also provides abundant precaution.

- The piping network should be built effectively because pipes are a crucial component of this system.

- The diagram that illustrates different specifications or information should be paste into such a place which gives easy visibility.

Fire Hydrant system Price In Pakistan

Universal Fire Protection CO Pvt provides all the firefighting equipment Fire Alarm System, Fire Hydrant, and Fire Sprinkler System at very reasonable prices. We provide the best services to our clients at comparative prices. Our aim is to provide good standard fire suppressor products at quite cheap rates.

Buy Fire Hydrant System in Pakistan

Universal Fire Protection CO Pvt provides services to commercial, industrial, government, and other facilities. With time the chances of fire disasters increase and it leads to the evolution of firefighting products. With these evolutions, we also upgrading our products and services to satisfy our customers. Our regular upgrading gives us a competitive edge in the market. Purchase best standard fire hydrant system from Universal Fire Protection CO Pvt. Feel free to contact us to get a Quotation.